How to Build a Reorder Tool for Amazon FBA and Retail: A Step-by-Step Guide

A robust reorder tool can make inventory management seamless for Amazon FBA and retail businesses. By leveraging tools like Google Sheets, you can create a dynamic system to monitor stock levels and determine reorder timing. This approach minimizes stockouts, optimizes cash flow, and ensures smooth operations. Here's a detailed guide to building an effective reorder tool using key inventory metrics and logical formulas.

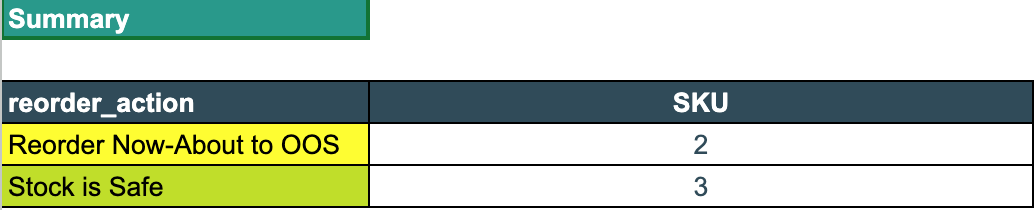

Preview of the reorder tools

Summary: This table shows the actionable statuses of SKUs based on current inventory, lead times, and safety stock thresholds.

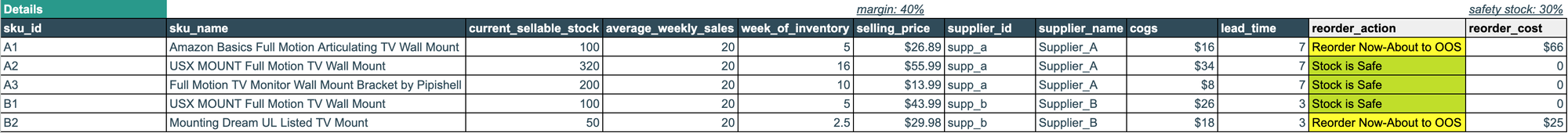

Details: The detailed breakdown below provides a closer look at each SKU's current status, including inventory metrics, supplier information, and suggested actions.

Preview on Google Sheet

Insights and Actions

- Critical Reorders (Reorder Now - About to OOS)

SKUs such as A1 and B2 are nearing critical stock levels and should be reordered immediately to prevent stockouts. - Healthy Inventory (Stock is Safe)

SKUs like A2, A3, and B1 have sufficient inventory levels and do not require immediate action.

Next Steps

- Prioritize Reorders: Focus on SKUs flagged as “Reorder Now” to maintain availability.

- Review Supplier Lead Time: Ensure orders are placed early to accommodate lead times.

- Optimize Reorder Costs: Calculate reorder costs for flagged SKUs and plan the budget accordingly.

This approach ensures a balance between stock availability and optimized inventory costs.

Key Variables for Reorder Tool in Google Sheets

To create an efficient reorder tool, start with these essential variables:

- Current Sellabel Stoçk

The number of units currently available in stock. This forms the baseline for evaluating when to reorder. - Average Weekly Sales (AWS)

Weekly sales trends to capture broader demand patterns.=SUM(Sales Range)/Number of Weeks - Weeks of Inventory (WOI)

A broader metric than DOI, offering insights on stock longevity over weeks.

Formula:=Current Inventory / AWS - Lead Time (LT)

The number of days between placing a reorder and receiving stock, including supplier processing and shipping time. - Supplier Name

Track who supplies the product to streamline communication during reordering. - Safety Stock

A reserve stock to prevent stockouts.

Explanation of Assumptions

1. Safety Stock (30%)

Safety stock acts as a buffer to protect against unexpected fluctuations in demand or delays in supply chain lead times. Setting safety stock at 30% means maintaining an extra inventory level that is 30% of the average weekly sales.

For example:

- If average weekly sales = 20 units

- Safety stock = 20 × 30% = 6 units

This ensures that even if demand increases unexpectedly or suppliers are delayed, you can continue fulfilling orders.

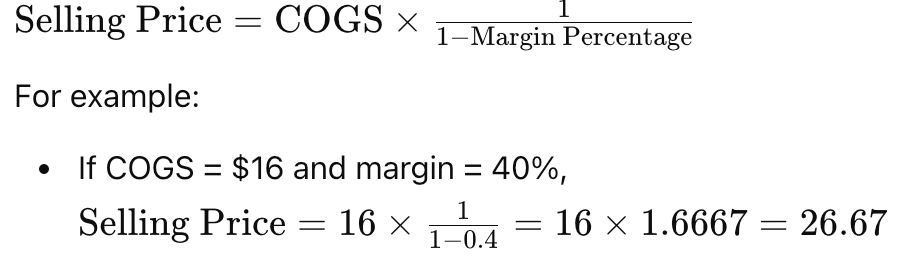

2. Margin (40%)

Margin is the difference between the selling price and the cost of goods sold (COGS), expressed as a percentage of the selling price. Assuming a 40% margin means:

This pricing strategy ensures that the business earns 40% profit on each unit sold after covering the cost of goods.

How Assumptions Impact Reorder Planning

- Safety Stock at 30%:

- Ensures stock availability during peak sales or unforeseen demand surges.

- Reduces the risk of stockouts but slightly increases holding costs.

- Margin at 40%:

- Helps set competitive pricing while ensuring profitability.

- Allows room for promotional discounts without going into negative margins.

These assumptions are designed to balance efficiency and profitability, aligning with Amazon FBA's dynamic sales environment.

The Logic Behind Reordering

By combining these variables, you can create a decision-making formula in Google Sheets to automate reorder recommendations. Here’s a sample logic:

=IFS(Current Stock <= Safety Stock, "Reorder Now - About to OOS",

Current Stock > 1.3 * Safety Stock, "Stock is Safe",

AND(Current Stock > Safety Stock, Current Stock < 1.3 * Safety Stock), "Reorder Soon")Explanation of the Logic:

- Reorder Now: Triggers when stock levels are at risk of going out of stock (OOS) based on lead time.

- Reorder Soon: Suggests reordering when inventory is above lead time but nearing critical levels.

- Stock is Safe: Indicates sufficient stock availability.

Tips to Enhance the Tool

- Dynamic Updates

Use Google Sheets integrations like Apps Script or APIs to automatically fetch sales and inventory data. - Safety Stock Calculation

Add a buffer stock to handle demand spikes or supplier delays. Formula:Safety Stock = (Max Daily Sales × Max Lead Time) - (Average Daily Sales × Average Lead Time) - SKU Segmentation

Use ABC analysis to categorize SKUs and prioritize high-value or high-demand products for tighter monitoring. - Visualization

Create dashboards with color-coded indicators (e.g., red for "Reorder Now") to improve readability and decision-making.

Conclusion

An effective reorder strategy is about balancing cost and availability. By incorporating reorder logic into tools like Google Sheets and analyzing real-time data, you can improve operational efficiency, avoid stockouts, and maximize profitability.

Takeaway: Stay proactive with inventory management, and remember that consistent monitoring of key variables like lead time, sales velocity, and current stock levels is crucial to success. With a smart reorder tool, you’re not just saving time—you’re building a more resilient business.

What’s your reorder strategy? Share your insights or challenges below—let’s collaborate to refine our approaches!